Technical Data

- Flow( Q) : Max 180 m3/h

- Head ( H ): Max 330 m

- Discharge: Max. 3000 lpm

- Rating: 0.5H.P. to 100H.P.

- Liquid Temp: -40° C to +180° C.

When it comes to water treatment, efficiency and reliability are key. That's why vertical multistage centrifugal pumps have become the go-to choice for many water treatment facilities

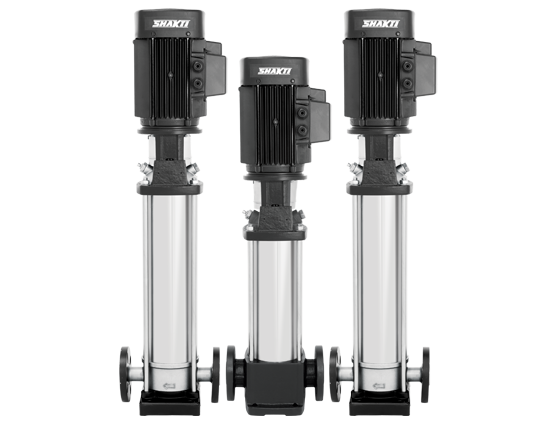

The SCR Pumps are vertical multistage centrifugal pumps that are not self-priming. Their unique in-line design allows them to be set up in a single horizontal pipe system, ensuring that both the suction and discharge ports align horizontally and share identical pipe dimensions. This configuration results in a more streamlined pump design and piping layout.

SHAKTI offers SCR pumps in a range of sizes and stages, tailored to deliver the necessary flow rates and pressures for diverse applications, spanning from household to industrial settings.

Each pump unit boasts optimized hydraulics and can be equipped with various connection types, outer sleeves, and components. Additionally, the construction material (MOC) for SCR pumps varies based on specific application requirements

Vertical multistage centrifugal pumps can handle a wide range of fluids, making them suitable for various water treatment applications. Whether it's pumping clean water, wastewater, or chemically aggressive liquids, these pumps can adapt to different environments.

The versatility of vertical multistage centrifugal pumps allows water treatment facilities to optimize their processes and handle diverse fluid requirements efficiently. This adaptability ensures that the pump system can be easily integrated into existing water treatment processes without significant modifications.

Our range of pumps and motors is meticulously crafted using AISI-304 and AISI-316 stainless steel. This choice of material not only offers exceptional wear resistance but also significantly reduces the risk of corrosion. This is particularly beneficial when handling cold water with minimal chloride content, ensuring longevity and reliability.

The inherent properties of stainless steel, such as its lightweight nature, simplify the handling of these pumps during installation. This results in cost savings due to reduced equipment requirements and less time spent on installation and servicing tasks.

Furthermore, the robust wear resistance of stainless steel ensures that even after servicing, the pumps retain their efficiency and durability, mimicking a new-like performance.

The use of vertical multistage centrifugal pumps in water treatment offers numerous benefits, including energy efficiency, space-saving design, high pressure performance, durability, and versatility. By utilizing these pumps, water treatment facilities can achieve optimal performance while minimizing costs and environmental impact.

When it comes to water treatment, efficiency and reliability are key. That's why vertical multistage centrifugal pumps have become the go-to choice for many water treatment facilities. In this article, we will explore the top 5 benefits of using these pumps, ranging from their exceptional energy efficiency to their space-saving design.

Vertical multistage centrifugal pumps are known for their ability to deliver high flow rates at relatively low energy consumption. This not only saves on operational costs but also reduces environmental impact. These pumps utilize multiple impellers stacked in series, allowing them to generate high pressure efficiently. By minimizing energy wastage, water treatment facilities can significantly reduce their carbon footprint and operate more sustainably.

Additionally, the energy savings achieved with vertical multistage centrifugal pumps can result in substantial cost reductions over time.

Unlike other pump types, vertical multistage centrifugal pumps have a compact design that allows for vertical installation. This makes them ideal choices for applications where space is limited. With their small footprint, these pumps can be easily integrated into existing water treatment systems, optimizing the use of available space.

Whether it's retrofitting an existing facility or designing a new one, the space-saving design of vertical multistage centrifugal pumps provides flexibility and efficiency in water treatment plant layouts.

Thanks to their innovative design, vertical multistage centrifugal pumps can handle high-pressure applications with ease. This makes them perfect for water treatment processes that require consistent pressure levels. Whether it's boosting water supply to higher elevations or maintaining adequate pressure for filtration systems, these pumps deliver reliable performance. The ability to handle high pressure ensures that water treatment facilities can meet the demands of their operations without compromising on quality or efficiency.

These pumps are built to last. With their robust construction and high-quality materials, they can withstand the demanding conditions often found in water treatment facilities. Corrosion-resistant materials, such as stainless steel, are commonly used for the pump components, ensuring longevity and reliability.

Furthermore, the robust wear resistance of stainless steel ensures that even after servicing, the pumps retain their efficiency and durability, mimicking a new-like performance.

Vertical multistage centrifugal pumps are designed to withstand the rigors of continuous operation, reducing downtime and maintenance costs. Their durability makes them an excellent investment for water treatment facilities looking for long-term solutions.

Filtration and transfer at waterworks, Distribution from waterworks, Pressure boosting in mains, Pressure boosting in high-rise buildings & hotels.

Cooling and air-conditioning systems (refrigerants), boiler feed and condensate systems, machine tools (cooling lubricants), aquafarming.

Ultra-filtration systems, Reverse osmosis systems, Softening, ionising, demineralizing systems, Distillation systems, Separators, Swimming pools.

We offer a complete range of pumps and motors which as a standard are made completely of stainless steel AISI-304 and AISI-316. This provides for good wear resistance and a reduced risk of corrosion when pumping ordinary cold water with a minor content of chloride.

Stainless steel means low weight facilitating the handing of pumps and resulting in low equipment cost and reduced installation and service time. In addition pumps will be as new after service due to the high wear resistance of stainless steel.